Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Product Features

- Fast cure

- Excellent adhesion

- Solvent free

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Adhesive & Sealant End Applications

- Coating End Applications

Properties

- Appearance

- Yellow brown

- Mechanical Properties

Value Units Test Method / Conditions Glass Transition Temperature 79 °C DSC Tensile Strength 51 MPa - Flexural Strength 108 MPa - Compressive Strength 75 MPa - Elastic Modulus 2309 MPa - Lap Shear Strength (Sand blasted substrate)* 20 MPa - - Typical Properties

Value Units Test Method / Conditions Viscosity (at 25°C) 700 cPs ASTM D2196 Technology Phenalkamine - - Color 13 Gardner ASTM D1544 Amine Value 357 mg KOH/g ASTM D2074 Theoretical Active Hydrogen Equivalent (based on total product weight) 270 - - Gel Time (at 25°C, 50 g) 25 minutes - Thin Film Dry Hard Time (at 25°C, at 200 micron) 4.5 hours ASTM D5895 Thin Film Dry Hard Time (at 5°C, at 200 micron) 15 hours ASTM D5895 Thin Film Dry Hard Time (at 0°C, at 200 micron) 24 hours ASTM D5895 Solid Content 100.0 % - Parts Per Hundred Resin/Rubber (PHR) 50 - - Mix Viscosity (at 25°C) 35 cPs - - Note

*Test specimen cured at 40°C for 16 hours with liquid epoxy (EEW 190)

Technical Details & Test Data

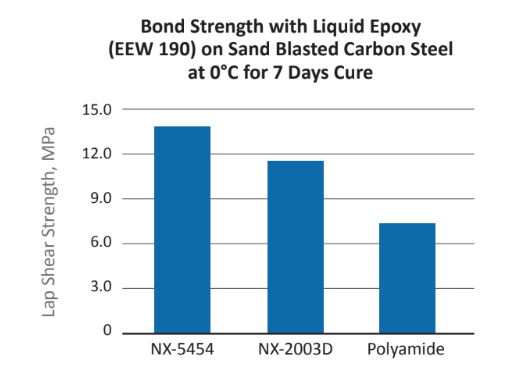

- Epoxy Curing Agents

- Bonding Under Adverse Conditions

Packaging & Availability

- Supplied by