Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Product Benefits

- Excellent combination of rapid cure and long pot-life at both ambient and low (<5°C/40°F) temperatures

- Continues to chemically crosslink at very low temperatures (<0°C/32°F)

- Good adhesion to poorly prepared surfaces and green concrete

- Moisture tolerant during cure

- Excellent early water resistance

- Very good chemical resistance

- Good flexibility

- Compatible with most epoxy resins, solvents and their blends

- Superior corrosion resistance mitigating the need for anticorrosion pigments

- Non-critical mix ratio

- No induction time required

- Non-toxic and non-corrosive

- Solvent and benzyl alcohol free

- Based from natural, renewable, non-food chain raw material feedstock

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Coating End Applications

- Use Level

- 40 - 50 (phr, EEW 190)

- Product Applications

- Cardolite NC-558 is usable in high solids or solvent free surface tolerant marine, industrial maintenance, protective, and floor coatings.

- Good chemical resistance and suitability for contact with potable water (Dependent on country regulations) make this curing agent especially acceptable for concrete or metal tank linings and pipe coatings.

- It can be used for coating applications under cold and humid conditions, even over damp and poorly prepared surfaces.

- This product’s fast cure and good hardness make it ideal for applications requiring fast return to service.

- Its ability to cure over a wide temperature range and non-critical mix ratio can bring coatings broad application latitude.

Properties

- Color (Properties)

- Physical Form

- Appearance

- Amber liquid

- Typical Properties

Value Units Test Method / Conditions Color max. 17 Gardner ASTM D1544 Viscosity (at 25°C) 500 - 1,500 cPs ASTM D2196 Amine Value 320 - 360 mg KOH/g ASTM D2074 Active Hydrogen Equivalent (based on total product weight) 95 - - Volatile Loss max. 4.5 wt.% ASTM D2369-98 Density (at 25°C) 8.15 - 8.35 lbs/gal ASTM D1475 Flash Point min. 104 °C ASTM D93 - Film Properties

Value Units Test Method / Conditions Film Appearance (Over Dry Concrete) Clear, glossy - - - Cured Properties

Value Units Test Method / Conditions Thin Film Dry Times 8 Mils (at 0°C, at 200 micron, hard) 32 hours ASTM D5895 Thin Film Dry Times 8 Mils (at 0°C, at 200 micron, through) 45.5 hours ASTM D5895 Thin Film Dry Times 8 Mils (at 0°C, at 200 micron, touch) 8.5 hours ASTM D5895 Thin Film Dry Times 8 Mils (at 25°C, at 200 micron, hard) 10 hours ASTM D5895 Thin Film Dry Times 8 Mils (at 25°C, at 200 micron, through) 15.5 hours ASTM D5895 Thin Film Dry Times 8 Mils (at 25°C, at 200 micron, touch) 4.5 hours ASTM D5895 Thin Film Dry Times 8 Mils (at 5°C, at 200 micron, hard) 22 hours ASTM D5895 Thin Film Dry Times 8 Mils (at 5°C, at 200 micron, through) 23 hours ASTM D5895 Thin Film Dry Times 8 Mils (at 5°C, at 200 micron, touch) 8 hours ASTM D5895 Liquid Epoxy Resin (EEW 190) 100 pbw - Cardolite NC-558 Content 50 pbw - Mix Viscosity (at 25°C) 3780 cPs - Gel Time (at 25°C, 50 g) 40 minutes NTM-15 Film Appearance (at 7°C, 95% RH) Blush - Visual Glass Transition Temperature 61* °C DSC Tensile Strength 41* MPa - Flexural Strength* 105 MPa - Compressive Strength 56* MPa - Elastic Modulus 1985* MPa - Lap Shear Strength (Sand blasted substrate)* 21 MPa - - Note

*Test specimen cured at 40°C for 16 hours with liquid epoxy (EEW 190)

Technical Details & Test Data

- Bonding Under Adverse Conditions

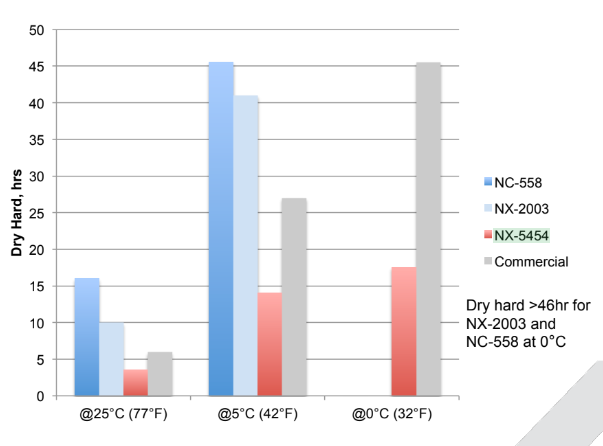

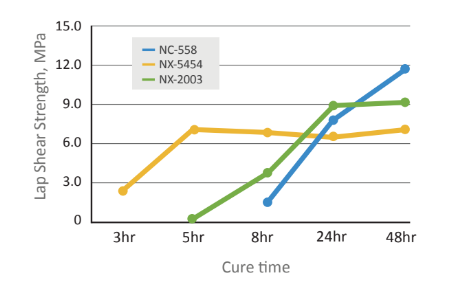

- Cure Speed with D.E.R. 353

- Hardness Development

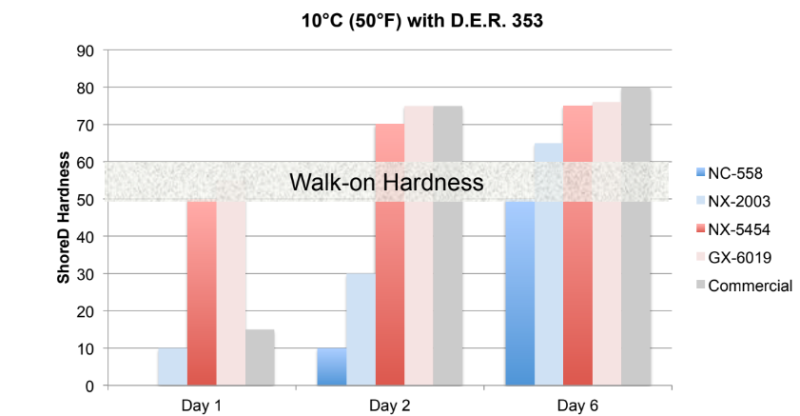

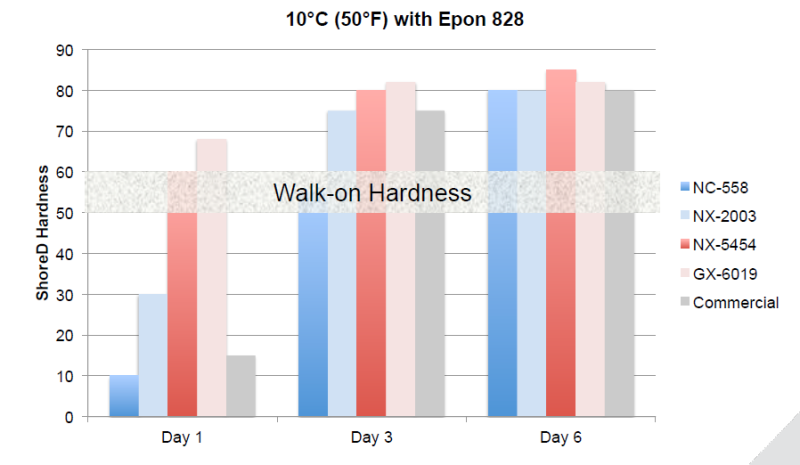

- Hardness Development at 10°C with D.E.R. 353

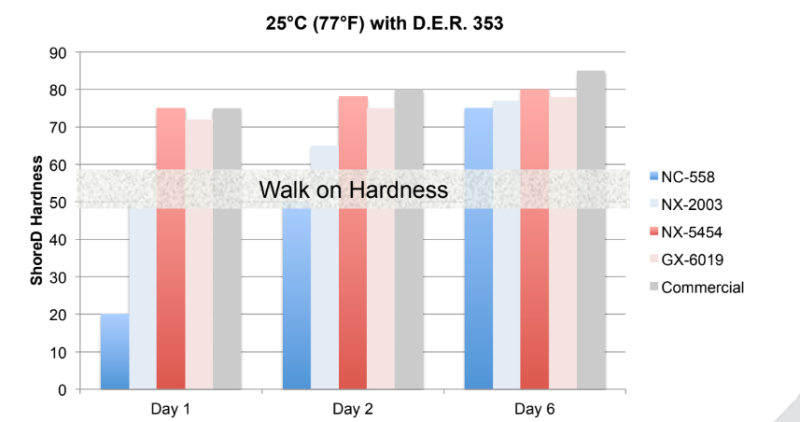

- Hardness Development at 25°C with D.E.R. 353

- Hardness Development at 10°C with Epon 828

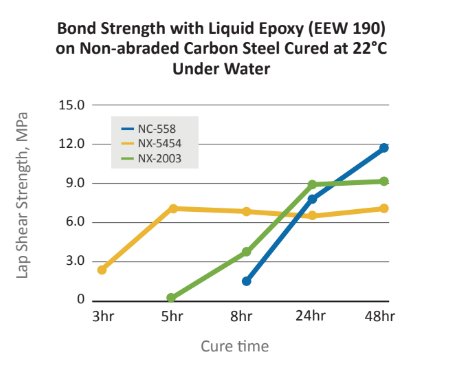

- Bonding Under Water

- Bond Strength with Liquid Epoxy (EEW 190) on Non-abraded Steel Cured at 22°C Under Water

- Lap Shear Strength On Plastics

Curing Agents

Lap shear strength on plastics(MPa) ABS Failure Mode Nylon Failure Mode PC Failure Mode PVC Failure Mode Acrylic Failure Mode PE Failure Mode PP Failure Mode NC-558 3.9 CF/AF 2.4 CF/AF 5.3 SF 3 CF/AF 3.7 SF 1.6 CF/AF 1.9 CF/AF

- Cured with Liquid epoxy(EEW=190) at 40°C/16hr

- Substrate pretreatment: sand paper polish+ Ethanol clean

- Failure Mode: CF: Cohesive failure, AF: Adhesive Failure SF: substrate failure

Packaging & Availability

- Supplied by

Storage & Handling

- Shelf Life

- 6 months

- Storage Condition

Cardolite products may absorb moisture and carbon dioxide when left in open containers, which could result in increased viscosity, discoloration, reduction of reactivity, and/or crystallization of the products. These products should be kept tightly sealed in their original containers when not in use, and stored in a cool, dry place.