Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Cleaning Ingredients Functions

- Fluids & Lubricants Functions

- Industrial Additives Functions

- Technologies

- Product Families

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Fluids & Lubricants Features

- HII Features

Applications & Uses

- Markets

- Applications

- Applicable Processes

- Compatible Substrates & Surfaces

- Fluids & Lubricants Type

- Coating End Applications

- Fluids & Lubricants End Use

- Home Care Applications

- I&I Cleaning Applications

- Industrial Additives End Use

- Use Level

- 0.25 – 1.0 %

- Product Applications

- Alkaline metal cleaners

- Synthetic coolants & cutting fluids

- Industrial cooling towers

- Water based lubricants

- Low foam alkaline cleaners

- Radiator fluids and cleaners

- Water based paints & coatings

Properties

- Physical Form

- Soluble In

- Appearance

- Clear yellow liquid (at 25°C)

- Soluble in

- Water, alcohol and glycol

- Insoluble in

- Solvents and oils (10% by weight)

- Typical Properties

Value Units Test Method / Conditions Density (at 25°C) approx. 1.0 g/ml - - Specifications

Value Units Test Method / Conditions Color max. 5 Garden Solid Content 43.0 - 47.0 % - pH Value 9.0 - 11.0 - - Active Content 45 % - - Product Properties

- Corrosion inhibitor for metal in aqueous systems at pH ≥ 7

- Effective on multiple metals including aluminum, brass & copper

- Prevents flash rust on steelNot stable in acid systems

- Low - moderate foaming

- Hydrotrope for alkaline systems

- Excellent corrosion protection on steel, aluminum, & yellow metals/alloys

- Multipurpse corrosion inhibitor

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Hydrotrope Data

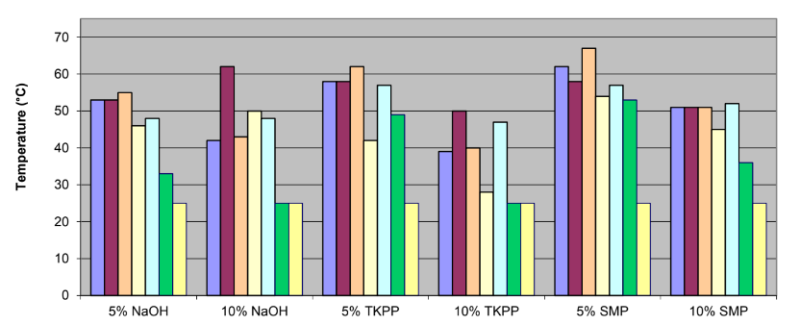

DeCORE AFCI-45 is also an excellent hydrotrope for alkaline systems as shown in the graph below. Performance was determined and compared to several other DeForest hydrotropes and to SXS-40.

Each hydrotrope was solubilized in a caustic or alkaline electrolyte solution followed by addition of nonylphenol ethoxylate (NPE-9.5). Each sample was heated to the temperature at which the NPE-9.5 clouds out of solution. The higher the cloud point temperature, the more efficient the hydrotrope.

Key: NaOH = Sodium Hydroxide, SMP = Sodium Metasilicate Pentahydrate, TKPP = Tetrapotassium Pyrophosphate- Cloud Points of Test Solutions: 1% NPE-9 + 1.5% Hydrotrope (as-is), 97.5% Electrolyte

- Corrosion Testing using DeCORE AFCI-45

Metal Panel Submersion Test at Room Temperature

The bottom half of each metal panel was submerged in solution containing 0.25% - 1.0% DeCORE AFCI-45 by weight, in hard water (100 ppm as CaCO₃ & 71 ppm as chloride) at room temperature. The top half of the panel was exposed to the vapor phase in closed glass containers. All results are after 12 weeks elapsed.

Steel Panels: SAE 1010 Cold rolled steel (mild carbon)

Aluminum Panels, #2024 Bare Aluminum 90 Days Room Temperature- Bottom half of panels are submerged in solution containing corrosion inhibitor, top half of panels are in the vapor phase.

- Solution contains 0.25% to 1.0% by weight corrosion inhibitor in hard water (100ppm CaCO₃ / 71ppm as chloride).

Copper Panels: #110 Copper (99.95% Cu) 90 Days Room Temperature

Brass Panels: #260 Brass Alloy (30% Zn / 70% Cu)

2024 Bare Aluminum (1 Year RT)

SAE 210 Cold Rolled Steel (90 Days)110 Copper Panels (1 Year RT)

260 Brass Panels (1 Year RT)

- Bottom half of panels are submerged in solution containing corrosion inhibitor, top half of panels are in the vapor phase

- Solution contains 0.25% to 1.0% by weight corrosion inhibitor in hard water (100ppm CaCO₃ / 71ppm as chloride)

- Metal Panel Submersion Test

Test at Elevated Temperature & High Chloride Environments

Test Conditions- Hard Water Solutions: 300 ppm as CaCO3 & 210 ppm as chloride

- DeCORE AFCI-45 level tested: 1.0% by weight (0.5% active)

- Solution pH: Solutions were adjusted with 0.1N NaOH from pH 6.25 to pH 8.75 - 9.0.

- Time/Temperature: 24 hours at Room Temperature (RT) and 200°F

The bottom half of each metal panel was submerged in solution whereas the top half of the panels were exposed to the vapor phase in closed glass jars. Controls do not contain corrosion inhibitor.

The following results indicate DeCORE AFCI-45 is an effective inhibitor for multiple metals under these test conditions.

Panels from left to right: RT control, RT w/inhibitor, 200°F w/inhibitor, 200°F control

Steel Panels: SAE 1010 Cold rolled steel (mild carbon)

Aluminum Panels, #2024 Bare Aluminum

Copper Panels: #110 Copper (99.95% Cu)

Brass Panels: #260 Brass Alloy (30% Zn / 70% Cu)

- Flash Rust Prevention

Flash rust can occur on steel after any wet method of surface preparation as the surface dries. It can occur quickly – within minutes- or at most, after a few hours. The following quick-screen test shows that DeCORE AFCI-45 is an effective flash rust inhibitor for cold rolled steel.

- First Beaker: Acidified tap water (pH 7.01) with a few drops of a 10% citric acid solution to final pH 5.35

- Second Beaker: 1% by weight DeCORE AFCI-45 added to acidified tap water to final pH 5.39

- Third Beaker: Acidified distilllled water (pH 5.53) with a few drops of a 10% citric acid solution to final pH 3.45

- Fourth Beaker: 1% by weight DeCORE AFCI-45 added to acidified distilled water to final pH 5.38

A cold rolled steel panel was placed into each solution and allowed to soak for ~1 hour at room temperature without covering the beakers. No rust was observed in the liquid phase on any of the panels prior to removing from solution. The steel panels were removed and allowed to air dry without rinsing.

Flash rust forms on the panels without DeCORE AFCI-45 present in solution within a few minutes of air drying.

No flash rust forms on the panel with DeCORE AFCI-45 present.- Corrosion Test for Engine Coolants in Glassware

Independent laboratory testing of DeCORE AFCI - 45 was conducted in duplicate at 2.0% by weight in 98% ethylene glycol (Defcool-2, Defcool-3) and compared to a commercial coolant (Defcool-1) containing 98% ethylene glycol and typical OAT corrosion inhibitors.

ASTM-3184 Test Results Defcool-1 Defcool-2 Defcool-3 Average Max. Acceptable Weight Loss

Copper specimen - Wt. Change (mg) 1.1 mg 3.9 4.5 4.2 10 mg Solder specimen- Wt. Change (mg) 54.8 mg 55.1 55.5 55.3 30 mg Brass specimen- Wt. Change (mg) 0.6 mg 4.7 4.6 4.7 10 mg Steel specimen - Wt. Change (mg) 0.1 mg 1.3 0.4 0.9 10 mg Cast Iron specimen - Wt. Change (mg) -0.2 mg -0.4 -1.5 -0.95 10 mg Cast Aluminum specimen - Wt. Change (mg) -1.9 mg -2.8 -3.7 -3.3 30 mg

Packaging & Availability

- Supplied by