Enhanced TDS

Identification & Functionality

- Chemical Family

- CASE Ingredients Functions

- Technologies

- Product Families

Features & Benefits

- CASE Ingredients Features

- Product Features

- Elastomeric properties

- Excellent bond strength

- Low Tg

- Good water resistance

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Compatible Substrates & Surfaces

- Adhesive & Sealant End Applications

- Coating End Applications

Properties

- Color (Properties)

- Physical Form

- Appearance

- Yellow liquid

- Mechanical Properties

Value Units Test Method / Conditions Tensile Strength 17.6 MPa - Hardness 72 Shore D - Lap Shear Strength (Blasted steel furnace) 11.2 MPa - Elongation At Break 83 % - Glass Transition Temperature 24.5 °C - - Typical Properties

Value Units Test Method / Conditions Color max. 5 Gardner ASTM D1544 Viscosity (at 25°C) 2,600 - 4,000 cPs ASTM D2196 Hydroxyl Value 145 - 195 mg KOH/g ASTM D1957 Moisture Content max. 0.15 % Karl Fischer Density (at 25°C) 8.327 lbs/gal ASTM D1475 Flash Point min. 100 °C ASTM D93 Hydroxyl Equivalent Weight 288 - 387 g/mole Calculated Bio Content (Calculated) 79 % - Average Functionality 3.2 - - - Hydrolytic Stability

Value Units Test Method / Conditions Lap Shear Strength Control Sample 9.3 MPa - Lap Shear Strength (after 80°C/7days water immersion) 7.1 MPa - Reduction in Lap Shear Strength 24.7 % - - Cured Properties

Value Units Test Method / Conditions Thin Film Dry Times 8 Mils (at 5°C, at 200 micron, hard) 8.5 hours ASTM D5895 Thin Film Dry Times 8 Mils (at 5°C, at 200 micron, through) 14 hours ASTM D5895 MRS - 5 (Poly MDI; NCO eq. Wt 132.1) 40.3 - - Cardolite NX-9005 Content 100 pbw - Gel Time (at 25°C, 50 g) 52 minutes NTM-15 Hard Dry (at 25°C) max. 4.5 hours - Hard Dry (at 5°C) max. 18 hours - - Moisture Properties

Value Units Test Method / Conditions CO₂ Polymeric MDI (after 24hr) 16 ml - - Note

- Typical Property (Bio Content): Calculated values are estimated based on the amount of renewable raw materials used and processing conditions. Cardolite cannot guarantee the accuracy of these calculations.

- Mechnanical Properties:

- Formulation - NX-9005/PMDI = 100/40.3, Polymeric MDI (PMDI): Desmodur 44V20L, PAPI 27; NCO Index: 100

- Lap shear - Lap shear test done on blasted steel substrate or aluminum.

- Cure Condition: Room Temperature for 7 days

- Cured Properties: Formulation - NX-9005/PMDI = 100/40.3, Polymeric MDI (PMDI): Desmodur 44V20L; NCO index: 100

- Moisture Properties (Moisture Sensitivity: CO2 Evolution)

- Formula - 100 g of polyol/p-MDI +100 g of water, 1 Polymeric MDI (PMDI): PAPI 27

- Hydrolytic Stability:

- Formulation - Polyol Sample, (cured with PMDI at NCO index = 100) Polymeric MDI (PMDI): PAPI 27; Cure condition: 60°C/72hrs

- Lap shear test done on sand blasted steel substrate.

- Moisture Properties:

- Formula - 100g of polyol/p-MDI+100g of water)

- Polymeric MDI(PMDI): PAPI27

- Reduction on CO2 evolution indicates less moisture sensitivity

- NX-9005 exhibited better hydrophobicity: reduced moisture sensitivity

- NX-9005 system was less affected by high humidity cure condition

Regulatory & Compliance

- Certifications & Compliance

- Chemical Inventories

Technical Details & Test Data

- Cured With Liquid Epoxy

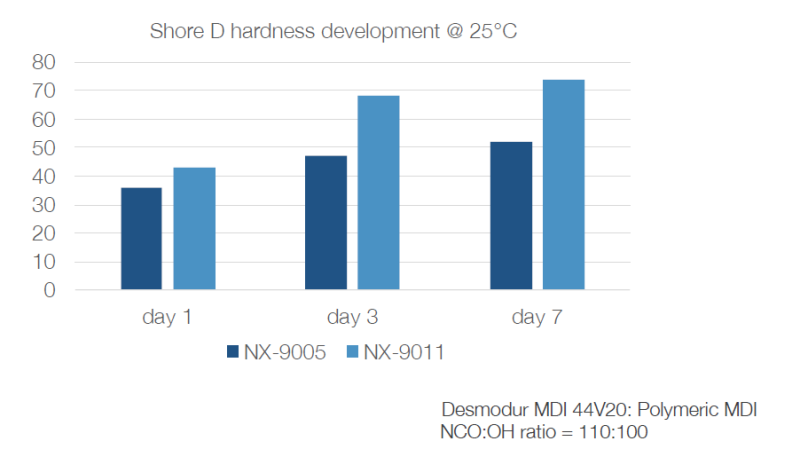

- Shore D hardness development at 25℃

- NX-9005 and NX-9011 showed fast hardness development

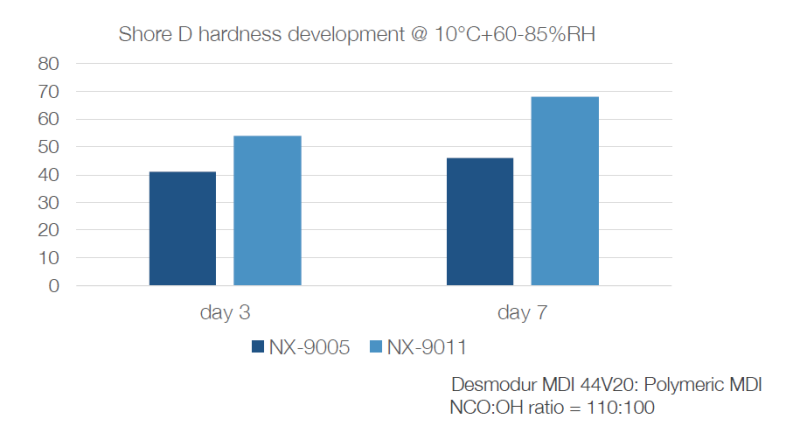

- Shore D hardness development @ 10℃+60-85%RH

- NX-9005 and NX-9011 exhibited good hardness development at low temperature.

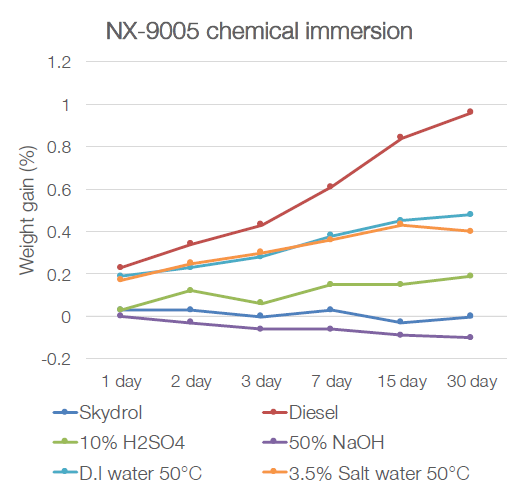

- Resistance Graphs

Chemical resistance

- NX-9005 system showed good chemical resistance to acid, alkaline, salt solutions, skydrol and Diesel.

- Improved alkaline resistance can be achieved by NX-9001

Packaging & Availability

- Supplied by

Storage & Handling

- Storage Condition

Cardolite products may absorb moisture and carbon dioxide when left in open containers, which could result in increased viscosity, discoloration, reduction of reactivity, and/or crystallization of the products. These products should be kept tightly sealed in their original containers when not in use, and stored in a cool, dry place.