Enhanced TDS

Identification & Functionality

- Chemical Name

- CASE Ingredients Functions

- Technologies

- Product Families

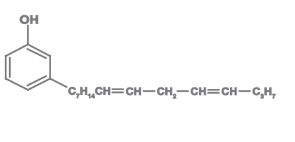

- Chemical Structure

Features & Benefits

- Labeling Claims

- CASE Ingredients Features

- Product Benefits

- Lowers viscosity while maintaining performance

- Preserves chemical and water resistance

- Good dilution and acceleration effects

- Improves flexibility

- Improves pigment wetting properties

- Usable on both sides on an epoxy formulation

- Low migration rate

- Low volatility and high flash point

- Non-toxic

- Based from natural, renewable, non-food raw material feedstock

Applications & Uses

- Markets

- Applications

- Compatible Polymers & Resins

- Coating End Applications

- Use Level

- max. 20% (of total resin weight)

- Product Applications

- Cardolite NX-2021 was designed as an accelerator and formulation tool to reduce VOC levels and viscosity on coating systems used in heavy duty marine, protective, industrial, and floor coatings.

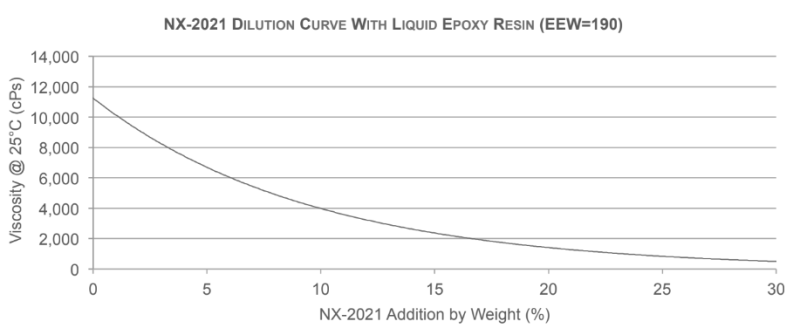

- Although higher in viscosity than some other modifiers, the structure of this product gives excellent dilution efficiency to help rapidly reduce viscosity for improved pigment wetting, flexibility, and general application properties.

- Coating physical properties such as water resistance, corrosion protection, chemical resistance, and gloss are not significantly compromised with the addition of NX-2021.

- This product can be added to either component of an epoxy system to provide good cure acceleration and replace or reduce levels of hazardous accelerators like nonylphenol.

Properties

- Appearance

- Yellow brown liquid

- Typical Properties

Value Units Test Method / Conditions Flash Point 260 °C ASTM D93 Solid Content max. 0.5 % - Bio Content (Calculated) 98 % - - Specifications

Value Units Test Method / Conditions Color max. 18 Gardner ASTM D1544 Viscosity (at 25°C) 45 - 75 cPs ASTM D2196 Density (at 25°C) 0.925 - 0.945 kg/l ASTM D1475

Regulatory & Compliance

- Chemical Inventories

Technical Details & Test Data

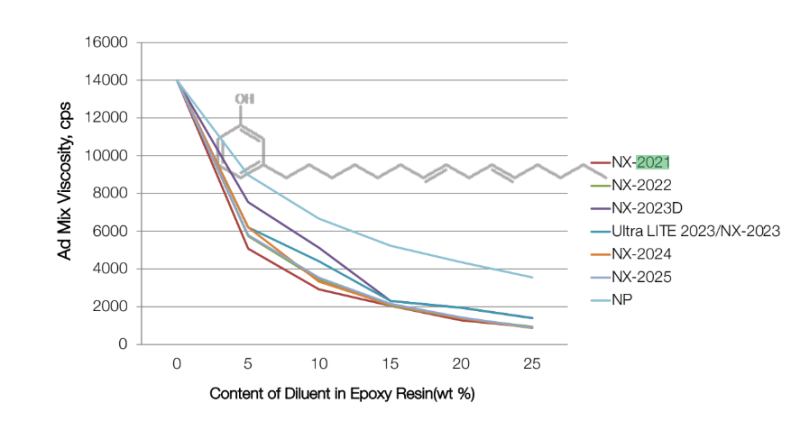

- Dilution Properties

Cardanol grades show much higher dilution power than Nonyl phenol.

- LCA Results

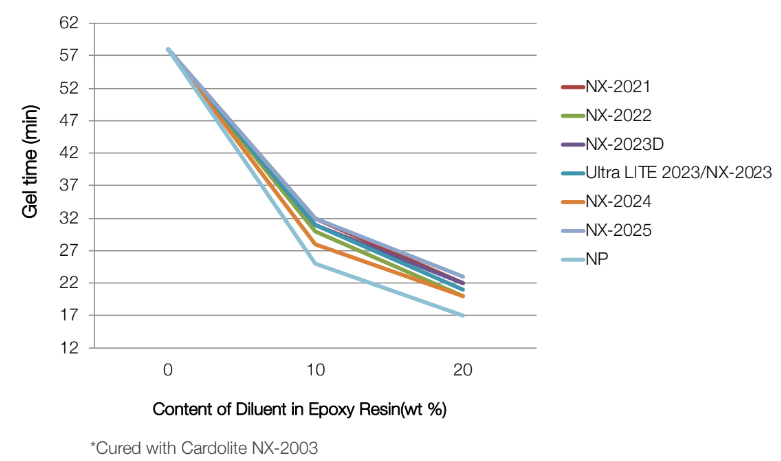

Results for each kg of NX-2021 Produced Impact category Unit Nut China Abiotic depletion (minerals) kg Sb-eq 1.47E-07 Abiotic depletion (fossil fuels) MJ 7.24 Global warming (GWP100a)* kg CO2-eq 0.72 Ozone layer depletion (ODP) kg CFC-11-eq 4.12E-08 Photochemical oxidation kg C2H4-eq 1.38E-04 Acidification kg SO2-eq 3.53E-03 Eutrophication kg PO4- eq 1.47E-03 - Acceleration Effect

Cardanol grades do not reduce gel time as much as Nonyl phenol.

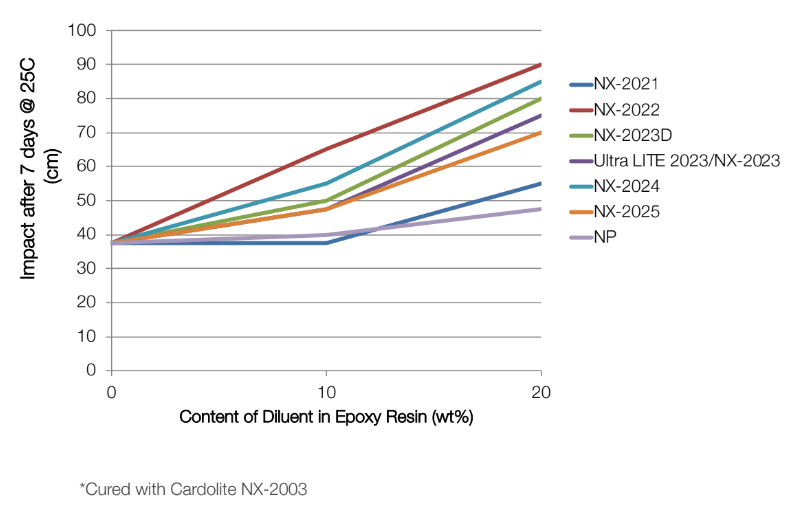

- Impact Resistance

Cardanol grades improve impact resistance of epoxy systems due to long aliphatic side chain. Improvement is more significant than for Nonyl phenol.

Packaging & Availability

- Supplied by

Storage & Handling

- Shelf Life

- 12 months

- Storage Condition

Cardolite products may absorb moisture and carbon dioxide when left in open containers, which could result in increased viscosity, discoloration, reduction of reactivity, and/or crystallization of the products. These products should be kept tightly sealed in their original containers when not in use, and stored in a cool, dry place.