Enhanced TDS

Identification & Functionality

Features & Benefits

- Labeling Claims

- Base Chemicals Features

- CASE Ingredients Features

Applications & Uses

- Markets

- Applications

- Compatible Substrates & Surfaces

- Base Chemicals End Uses

Properties

- Physical Form

- Appearance

- Yellow color liquid

- Mechanical Properties

Value Units Test Method / Conditions Tensile Strength 38 MPa - Hardness 80.0 Shore D - Lap Shear Strength (Blasted steel furnace) 14.3 MPa - Elongation At Break 6 % - Glass Transition Temperature 98 °C - - Typical Properties

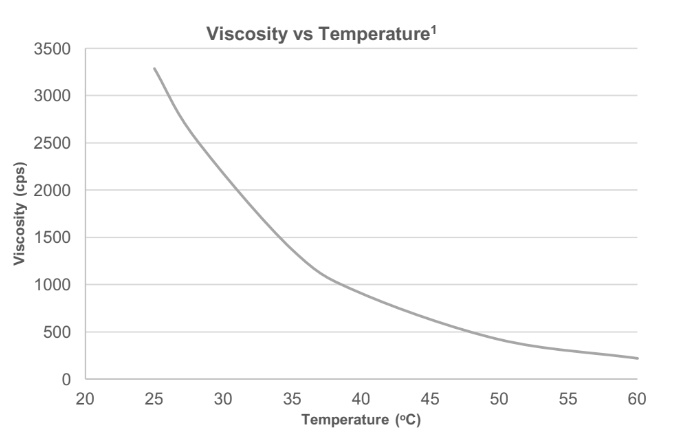

Value Units Test Method / Conditions Color 10 Gardner ASTM D1544 Viscosity (at 25°C) 2,000 - 4,000 cPs ASTM D2196 Hydroxyl Value 300 - 380 mg KOH/g ASTM D1957 Water Content max. 0.1 % Karl-Fischer Average Functionality 3.0 - - Bio Content (Theoretical Estimates) 61 % - - Hydrolytic Stability

Value Units Test Method / Conditions Lap Shear Strength Control Sample 17.2 MPa - Lap Shear Strength (after 80°C/7days water immersion) 7.6 MPa - Reduction in Lap Shear Strength 55.7 % - - Cured Properties

Value Units Test Method / Conditions Hard Dry (at 25°C) max. 3 hours - Hard Dry (at 5°C) max. 10 hours - - Hydrolytic Stability Conditions

NX-9008 (cured with PMDI (Polymeric MDI (PMDI): PAPI 27; Cure condition: 60°C/72hrs) at NCO index = 100).

- Note

Mechanical property formulations:

- NX-9008 (cured with PMDI (Polymeric MDI (PMDI): PAPI 27; Cure condition: 60°C/72hrs) at NCO index = 100)

- NX-9008/PMDI (Polymeric MDI (PMDI): Desmodur 44V20L, PAPI 27; NCO Index: 100) = 100/78.3

- Cure Condition: Room Temperature for 7 days

Regulatory & Compliance

- Certifications & Compliance

Technical Details & Test Data

- Viscosity Profile

- Bonding on Plastics and Composites

Lap Shear Strength² (MPa) Polyols¹ ABS Failure Mode³ Nylon Failure Mode³ PC Failure Mode³ PVC Failure Mode³ Acrylic Failure Mode³ PE Failure Mode³ PP Failure Mode³ Composite⁴ Failure Mode³ NX-9008 4.6 SF 2.1 CF/AF NA NA NA NA 1.4 CF/AF 15.4 CF - ¹Cured with polymeric MDI (PMDI): Desmodur 44V20L; NCO index: 100

- ²Substrate pretreatment: sand paper polish + ethanol clean

- ³Failure Mode: CF = cohesive failure, AF = adhesive failure, SF = substrate failure

- ⁴Composite: carbon fiber reinforced epoxy prepreg

Packaging & Availability

- Supplied by

Storage & Handling

- Storage Condition

Cardolite products will absorb moisture and carbon dioxide when left in open containers, which may result in increased viscosity, discoloration, reduction of reactivity, and/or crystallization of the products. These products should be kept tightly sealed in their original containers when not in use, and stored in a cool, dry place.